3D Printing in Manufacturing

Rapid Prototyping, Low-Volume Production, Virtual Inventory

RAPID PROTOTYPING

Prior to entering the phase of mass production, multiple iterations of prototypes are created for product structural and functional tests.

Before the use of 3D printing, this process often take weeks of coordination among both internal departments and external organizations.

Today, rapid prototyping is made possible with 3D printing solutions. Engineers and designers can 3D Print prototypes in-house to conduct tests swiftly.

LOW-VOLUME PRODUCTION

At times, a situation occurs wherein a manufacturer has to produce a small lot of components or parts. However, creating a mold for such small batch production is prohibitively expensive and time-consuming.

Given the challenge, manufacturer turns to 3D printers as the solution. 3D printing skips the need of custom-made mold and allows manufacturer to start components production immediately and cost-effectively.

VIRTUAL INVENTORY

Minimizing physical inventories has been an increasingly important practice for companies which actively pursuing cost savings.

Previously, companies need to set aside a sizable amount of funds to manufacture and manage inventory.

Now, companies begin to shift from physical inventory to virtual inventory. Spare parts are 3D printed as and when they are required.

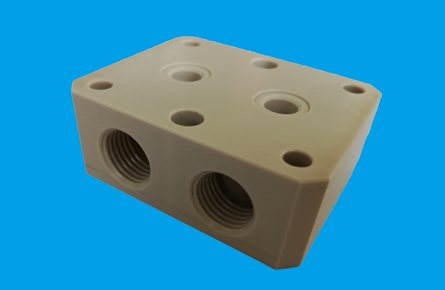

Components & Parts 3D Printed with INTAMSYS FUNMAT HT

FUNMAT HT

High Performance Functional Material 3D Printer

Constant-Temperature Chamber

Constant-Temperature Chamber

Chamber temperature over 70°C

High Temperature All Metal Nozzle

High Temperature All Metal Nozzle

All metal hotend that can go upto temperature of 400°C

Functional Material Capability

Functional Material Capability

Able to print PEEK, ULTEM (PEI), PC and many more